Home > Company Introduction

Company Overview

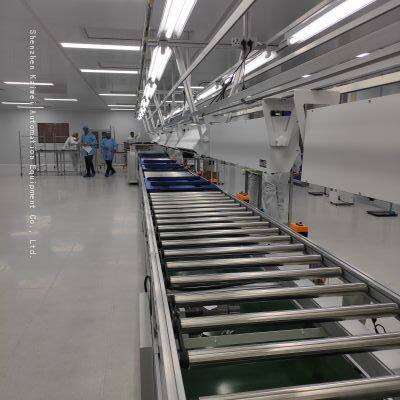

About Us Shenzhen Kaiwei Automation Equipment Co. , Ltd. is a high-tech Enterprise focusing on automatic assembly line. It has been engaged in the industry for many years, at the same time, the non-standard production line is customized to help enterprises realize the intelligent upgrading of production. With the concept of\"Technology-driven production, customized enabling manufacturing\", the company relies on a team of senior engineers such as mechanical design and electrical control to accurately meet customer needs, provide one-stop service from project planning, equipment manufacturing to commissioning training. Core products Household appliances assembly line: adapt to refrigerators, washing machines, etc. , integrated transportation, positioning, testing functions, can be flexibly adjusted to improve efficiency and pass rate. Automotive Battery production line: covering the whole process of power battery, high stability, high safety, in line with the strict standards of the automotive industry. Air conditioning assembly line: Modular design, adapt to multi-specification air conditioning, reduce labor intensity, realize flexible production. Non-standard customized production line: on-demand customization, breaking through the limitation of standard equipment, service electronics, new energy, medical and other fields. Corporate Advantage Uphold the\"Quality first, service first\", the establishment of the whole process quality control system, and well-known suppliers to ensure the reliability of components; 24-hour after-sales response, has served a number of home appliances, new energy leading enterprises, get a good reputation. In the future, the company iterates technology products and is committed to becoming a global leader in smart assembly line solutions.

-

ManufacturerBusiness Type

-

2010Year Established

-

YesOverseas Office

-

1,000-3,000 square metersFactory Size

Company Detail

Transparency is the foundation of our partnership. Below is a comprehensive overview of our operational metrics, from business scale to global market reach, giving you a clear picture of our capabilities.

-

51 - 100 People Total Employees

-

1-10 People Sales Staff

-

5-10 People Quality Inspectors

-

ISO9000 Product Certifications

-

US$1.5 Million - US$2.5 Million Annual Export Value

-

South America, Southeast Asia, Africa, Mid East, Eastern Asia, Western Europe, South Asia, Domestic Market Main Markets

-

Shenzhen Port, Guangzhou Port, Port of Shanghai, Ningbo-Zhoushan Port Port of Shipment

-

Yes Overseas Office

-

Electrical Appliance Production Line Main Industry

-

Quality ControlStrict quality control system We implement a full-cycle quality management system covering the R & D, production, delivery and after-sales stages. During the R & D phase, the core components undergo multiple performance tests to ensure technical reliability; during the production phase, we employ rigorous incoming inspection (for supply chain parts) , process quality monitoring (real-time tracking precision and process) , and final equipment acceptance (load testing simulating a real production scenario) . All quality data are traceable, each link has a special quality inspector supervision. Following industry quality standards, we ensure that each custom assembly line can meet the requirements of stable operation, high precision and long life, and lay a solid foundation for customers' efficient production.

Quality ControlStrict quality control system We implement a full-cycle quality management system covering the R & D, production, delivery and after-sales stages. During the R & D phase, the core components undergo multiple performance tests to ensure technical reliability; during the production phase, we employ rigorous incoming inspection (for supply chain parts) , process quality monitoring (real-time tracking precision and process) , and final equipment acceptance (load testing simulating a real production scenario) . All quality data are traceable, each link has a special quality inspector supervision. Following industry quality standards, we ensure that each custom assembly line can meet the requirements of stable operation, high precision and long life, and lay a solid foundation for customers' efficient production. -

Our ServicesFocusing on customer's production needs, we provide comprehensive and customized assembly line solutions Provide 3D layouts, process flow diagram, equipment parameter lists and cost quotes according to industry process standards. Industry Adaptability: specializes in electronics, auto parts, home appliances, has rich experience in customization, can meet the complex process requirements. 1. Requirements Communication: initial coordination to clarify basic information (product specification, capacity requirements, site size, budget scope) . 2. Solution customization: develop detailed solution after in-depth research; confirm and optimize with customer. 3. Manufacturing: Start production according to the plan, synchronize the progress, the whole process is supervised by the customer. 4. Installation and commissioning: provide on-site equipment installation, commissioning and commissioning to meet pre-set production standards. 5. Acceptance and delivery: submit technical documents and Operation Manuals to complete delivery after successful customer acceptance. 6. After-sales follow-up: regular follow-up and provide continuous support (repair, maintenance, upgrade) .

Our ServicesFocusing on customer's production needs, we provide comprehensive and customized assembly line solutions Provide 3D layouts, process flow diagram, equipment parameter lists and cost quotes according to industry process standards. Industry Adaptability: specializes in electronics, auto parts, home appliances, has rich experience in customization, can meet the complex process requirements. 1. Requirements Communication: initial coordination to clarify basic information (product specification, capacity requirements, site size, budget scope) . 2. Solution customization: develop detailed solution after in-depth research; confirm and optimize with customer. 3. Manufacturing: Start production according to the plan, synchronize the progress, the whole process is supervised by the customer. 4. Installation and commissioning: provide on-site equipment installation, commissioning and commissioning to meet pre-set production standards. 5. Acceptance and delivery: submit technical documents and Operation Manuals to complete delivery after successful customer acceptance. 6. After-sales follow-up: regular follow-up and provide continuous support (repair, maintenance, upgrade) . -

Company HistoryLaying the foundation for start-ups (2010-2013) In 2010, Shenzhen Kaiwei Automation Equipment Co. , Ltd. was established, focusing on the core business: Small and medium-sized enterprise information services and customized equipment research and development. Growth (2014-2018) The company has expanded its business scope, improved its supply chain, established a research and development team, and expanded its cooperation network. In 2017, the company made key breakthroughs, including product upgrades to assembly lines, two-speed chain assembly lines, heavy-duty production lines, cranes, transporters and non-standard custom equipment Stable (2019-current) The company focuses on core competencies, R & D and service upgrades, technological progress has been made in the fields of display screens, household appliances, air conditioning production lines, refrigerator production lines, new energy, automobile engine assembly, automatic assembly, robot automatic stacking, automatic packaging and cleaning workshops. The company has developed a mature business model, grown into an influential enterprise in the industry, and continues to create value for customers.

Company HistoryLaying the foundation for start-ups (2010-2013) In 2010, Shenzhen Kaiwei Automation Equipment Co. , Ltd. was established, focusing on the core business: Small and medium-sized enterprise information services and customized equipment research and development. Growth (2014-2018) The company has expanded its business scope, improved its supply chain, established a research and development team, and expanded its cooperation network. In 2017, the company made key breakthroughs, including product upgrades to assembly lines, two-speed chain assembly lines, heavy-duty production lines, cranes, transporters and non-standard custom equipment Stable (2019-current) The company focuses on core competencies, R & D and service upgrades, technological progress has been made in the fields of display screens, household appliances, air conditioning production lines, refrigerator production lines, new energy, automobile engine assembly, automatic assembly, robot automatic stacking, automatic packaging and cleaning workshops. The company has developed a mature business model, grown into an influential enterprise in the industry, and continues to create value for customers. -

Our TeamAdvantage of professional team Our team combines R & D, design, production and service professionals with an average of more than 15 years of experience in the field of automated assembly lines. The core R & D Team of senior engineers is well versed in key technologies such as automation and lean manufacturing, and has led hundreds of customised projects in electronics, automotive parts and home appliances, televisions, air conditioners, refrigerators, computers. The project execution team excels at efficient coordination, ensuring a seamless transition from requirements research to after-sales support. With a customer-centric mindset, we combine technical expertise and industry insight to reliably support customized solutions and long-term mandates.

Our TeamAdvantage of professional team Our team combines R & D, design, production and service professionals with an average of more than 15 years of experience in the field of automated assembly lines. The core R & D Team of senior engineers is well versed in key technologies such as automation and lean manufacturing, and has led hundreds of customised projects in electronics, automotive parts and home appliances, televisions, air conditioners, refrigerators, computers. The project execution team excels at efficient coordination, ensuring a seamless transition from requirements research to after-sales support. With a customer-centric mindset, we combine technical expertise and industry insight to reliably support customized solutions and long-term mandates.